At MTE Heat Treatment Ltd we provide sub contract services for the heat treatment and surface engineering of metals, specialising within the gear and spline industry. We are based in over 30,000 Sq Ft of custom-designed facilities in Slaithwaite, West Yorkshire with easy access to the motorway network. We service a broad customer base, including the automotive and heavy automotive sectors, marine, energy and precision engineering industries.

ABOUT OUR COMPANY

The layout of our plant has been designed to provide the most efficient work flows across the broad range of processes carried out by the company. The facilities have been equipped with high quality plant and machinery employing the latest technology in terms of equipment and testing facilities. Our continuous improvement program ensures the facilities are maintained to the highest standard. The work force is highly trained and qualified, benefiting from over 70 years of gear manufacturing and heat treatment experience onsite.

We pride ourselves in customer satisfaction, focused on meeting and exceeding your requirements. Our objective is to be a seamless part of your supply chain, providing a rapid and quality assured response to your needs.

OUR SERVICES

For Help with your requirements call 01484 850361 and ask for customer support

Heat Treatment

We offer a complete range of heat treatment processes from Carburising to Normalising. We also specialise in Precision Quenching.

Grinding

Grinding process including CNC external and gear tooth with addition manual capacity for internal, external and spline.

Induction Hardening

We offer an extensive range of modern induction hardening equipment providing high, medium and low frequency options with both single shot and scanning capabilities.

Shot Peening

Specialising in Shot Peening to improve the service life of geared components. Also offer a shot blast process to remove surface imperfections.

Gear Cutting

A well equipped machine shop offers Gear Hobbing, Shaping, Shaving and Broaching.

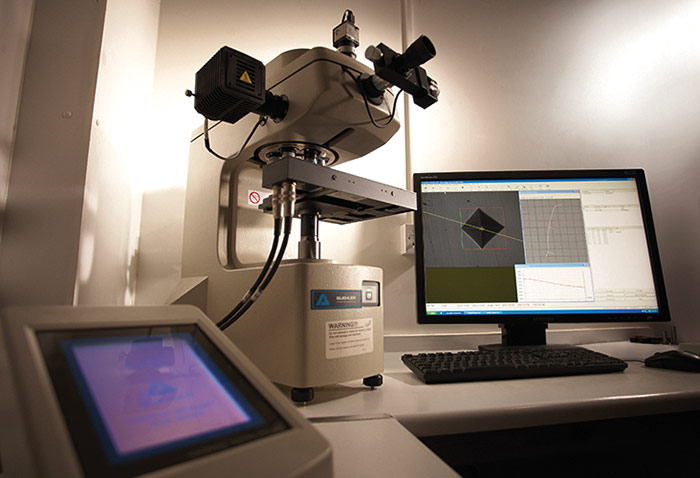

Laboratory

Fully equipped lab with facilities including CNC CMM with gear measurement. Optical spectrometer for precise chemical analysis. Full range of hardness from 1g micro vickers to Rockwell and Brinell. Contour measurement with MAHR. Microscope with image analysis facilities to complete any service from routine inspection, to failure analysis and process design.